When using a 300W car inverter https://heargrow.com/shop/ in southern Africa, if there is an issue with capacitor explosion, it may be related to local environmental conditions. Below are some factors that could affect the performance of electronic devices:

- Temperature: Much of southern Africa experiences warm to hot climates, especially during summer. High temperatures can accelerate the aging of electronic components and lead to overheating, particularly when heat dissipation is inadequate. If the cooling system of the inverter is not designed for high-temperature environments, internal components such as capacitors might fail due to excessive heat.

- Humidity: While some areas like the Kalahari Basin and the western coast are arid, other regions (such as the eastern coast) may have higher humidity levels. High humidity can cause electrical short circuits or corrosion, affecting the device’s operation.

- Temperature Variation: Large temperature differences between day and night can lead to material expansion and contraction. Over time, this can result in solder joint fatigue or other mechanical stress issues, impacting sensitive components like capacitors.

- Altitude: Although most populations reside in low-altitude areas, at higher altitudes, lower air density can reduce the effectiveness of natural convection cooling, making it harder for devices to dissipate heat.

- Vibration: If the inverter is installed in a vehicle, vibrations during travel can exert physical stress on internal circuit boards, especially on poor road conditions. Continuous vibration can damage solder joints or loosen fixed parts, eventually leading to failure.

- Power Quality: In some remote areas, the power supplied by the grid may be unstable with significant voltage fluctuations. Unstable input voltage increases the operational burden on inverters, particularly those lacking robust voltage regulation, putting additional strain on internal components.

- Insufficient Protection Rating: If the inverter design does not meet IP protection standards and cannot effectively prevent dust from entering the interior, dust accumulation can affect heat dissipation efficiency and cause localized overheating.

To avoid these issues, it is crucial to select a high-quality inverter suitable for local environmental conditions. Ensure the product has good heat dissipation design, appropriate protection ratings, and sufficient stability and reliability to handle potential harsh environmental factors. Regular maintenance checks can also help identify and resolve potential problems in a timely manner. If a capacitor explosion has already occurred, it is advisable to contact the manufacturer for technical support and consider replacing it with a model more suitable for use in the region.

Issue Feedback

Problem Analysis

Capacitors, when improperly used, can indeed explode upon being powered. For electrolytic capacitors, there are generally three common causes for such failures:

- Reverse Polarity: Electrolytic capacitors are polarized components, meaning they have a positive and a negative terminal. If these terminals are connected in reverse to the power supply, it can cause the capacitor to fail catastrophically.

- Overvoltage: Applying a voltage that exceeds the rated maximum voltage of the capacitor can lead to its breakdown. Capacitors are designed to operate within specific voltage limits, and exceeding these can result in failure.

- Leakage: Over time or under adverse conditions, electrolytic capacitors may start leaking their electrolyte. This leakage can be due to age, heat, or physical damage, and can eventually lead to failure.

Regarding the parameters provided by the capacitor supplier, it appears you’ve shared a link to a Weiyun (a Chinese cloud storage service) document. Unfortunately, I cannot directly access external links, including this one. However, if you can provide the details or specifications from the document, I would be able to help translate or explain them for you.

Contingency Analysis

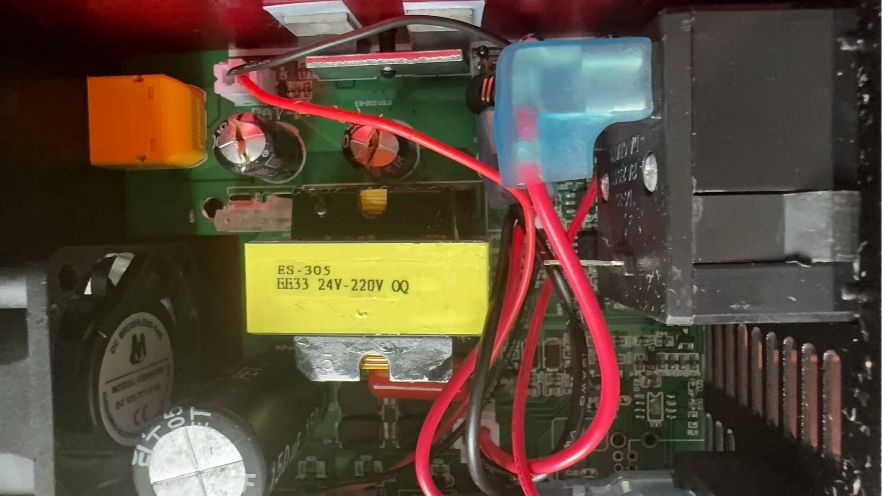

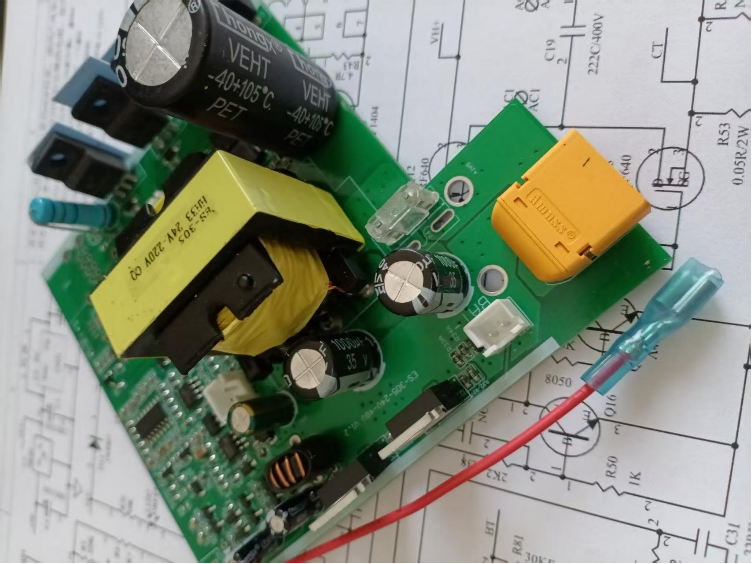

1:Component Analysis

Sample Analysis, Capacitor 1000uF 35V

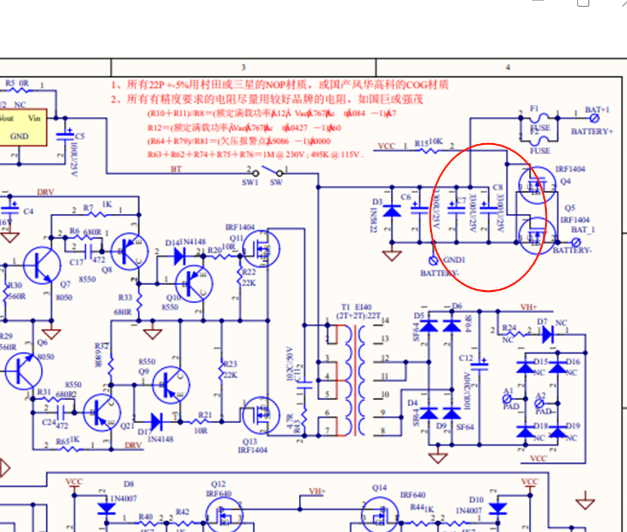

2:Circuit Analysis

At the battery terminal, there are no other components internally to cause interference

3:Perform circuit testing at 33V on five inventory boards

4:Suppliers

5:Vibration

Previously, our factory performed tests that demonstrated vibrations at certain frequencies are capable of fracturing components with tall leads.

Vibrations experienced during installation or transit cannot be ruled out as a potential cause for loosening of capacitor polarity, increased spacing between the aluminum foil and the oxide film, which may result in electrolyte leakage and reduced withstand voltage.

Corrective Actions and Measures

1:As of now, testing is underway on five inventory sample boards with a 33V power supply. No capacitors have failed or exploded, and all boards are operating as expected.

The 24V battery system reaches a maximum voltage of 29.5V, with 8 cells connected in series, each having a nominal voltage of 3.2V and a maximum voltage of 3.65V, leading to a highest possible voltage of 29.2V. Since the capacitors are specified with a rating of 35V, we are currently performing tests at 33V.

.

2:The leakage of electrolyte from the electrolytic capacitor and the resulting excess gas expansion may indicate a defect rate in the capacitor quality.

3:Alternatively, the electrolyte leakage could be a result of prolonged storage of the capacitors.

4:The manufacturer mentioned there is a defect rate.

Conclusion of Analysis

1:Polarity Reversal (excluded by the customer)

2:Overvoltage (excluded)

3:Defect Rate in Electrolytic Capacitors (admitted by the supplier)

4:Extended storage may have resulted in electrolyte leakage and decreased voltage withstand capability. It cannot be ruled out that the supplier’s stock consists of aged inventory.

5:Negative feedback voltage from interconnected circuits led to overvoltage conditions due to voltage stacking. Historically, solar controllers were consistently damaged in the system despite various modifications. It was later identified that other devices were introducing negative feedback voltage. Once these devices were repaired, the problem was resolved. Therefore, this potential cause should be ruled out.

6:Vibration as a cause (cannot be excluded, but is not considered the primary factor)

Derived Corrective Actions

If the problem is attributed to component issues, switch to a different supplier. Additionally, apply potting compound to large discrete components for protection.

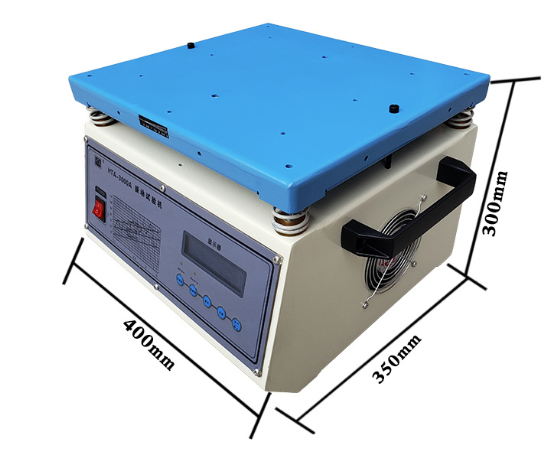

Testing and Analysis Environment

(Equipment Model, Testing Standards, and Other Relevant Information)

The MOSFETs used in this batch are of standard quality and provide good value for money. Nevertheless, it is suggested to consider using higher-quality MOSFETs where appropriate. To date, no association has been identified between the quality of the MOSFETs and the observed capacitor failures.

If you need it can contact us whenever possible https://heargrow.com/shop/

Services

Personal styling

Work one-on-one with our expert stylists to curate outfits that align with your unique taste, body type, and lifestyle.

Wardrobe refresh

Revamp your wardrobe. Our stylists will help you declutter, organize, and update your closet with fresh new pieces.

Alterations and tailoring

Ensure the perfect fit. From hemming to resizing, our skilled tailors will tailor your garments to perfection.

Virtual Shopping

Can’t make it to our store? Our virtual shopping assistance service allows you to shop from the comfort of your home.